Relative humidity can significantly impact broiler performance, especially at the early brooding stage of the production cycle. Consequently, having the capability to monitor and identify inconsistencies throughout sheds, will allow producers to identify if optimum humidity is being achieved.

In broiler houses, relative humidity should sit between 60 and 70%, anything above or below this can negatively impact bird health and performance.

For example, during the winter months, it’s not uncommon to see humidity levels increase above the optimum, resulting in damp bedding and potential health issues, so it is important producers adjust ventilation and heating daily to help avoid this.

Likewise, young chicks are particularly sensitive to low humidity, which is something to be mindful of before a new batch arrives. Young birds will often drink more to compensate for the dry environment, and birds that are even slightly dehydrated will not eat a sufficient level of food, which can result in reduced growth rates.

Variations in relative humidity at the early brooding stage can also result in uneven birds which don’t meet processor requirements, which can have a significant impact on the financial viability of the business.

Poultry farm case study

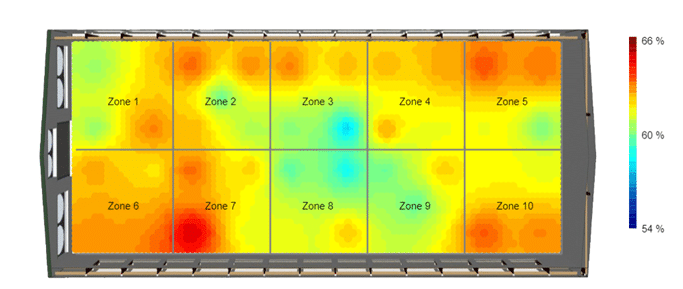

Below is a climate humidity map taken over a 24-hour period from a broiler shed housing 50,000-five-day old chicks. The red sections in the graph shows that relative humidity is higher than typically expected in some areas of the shed (figure 1).

In this example, high relative humidity can be seen in correlation with high ammonia and carbon dioxide levels, which can often result in respiratory problems as well as reduced performance. Here, regular monitoring of these parameters would be recommended and changes made to try and reduce variation throughout the shed. But, how can this be achieved?

Maintaining humidity levels in poultry sheds

There is still a level of uncertainty around the full extent of humidity variation and what can be done to maintain this throughout broiler houses, particularly at the early brood stage. But this is where the SenseHub™ Poultry solution fits in.

It can provide the insight required for consistent humidity to be achieved, as it collects and analyses real-time data from all of the key environmental and performance parameters that influence humidity levels.

One thing that can be done to improve relative humidity is to review and improve air circulation within sheds to help create a more consistent and optimum level of humidity for the age of the birds. And having the ability to closely monitor this through the SenseHub™ Poultry solution, will allow producers to change things if inconsistencies are seen.

To date, humidity has not been monitored that closely on farms, but we know it can have a significant impact on performance and therefore having accurate, real-time monitoring systems can allow producers to monitor this much more closely. Ultimately improved humidity levels will result in increased bird uniformity, health and welfare.

For more information on effective ways to collect, analyse and interpret humidity as well as many other environmental factors contact the SenseHub™ Poultry team on +44 (0)3303 204652 or info@sensehubpoultry.com.